If you've seen a bright white roof, then you may be familiar with TPO roofing. As one of the most common roof types of big commercial facilities, TPO has some of the best energy savings for single-ply membrane roofing!

Here at West Roofing Systems, we've been installing Single-Ply Membrane Roofing for over 40 years.

In this article, we cover everything you need to know about TPO roofing.

WHAT IS SINGLE-PLY MEMBRANE ROOFING?

West Roofing Systems Installs Single Ply Membrane Roof

West Roofing Systems Installs Single Ply Membrane RoofSingle-Ply Membranes are sheets of rubber and other synthetics that can be ballasted, mechanically fastened, or chemically adhered to insulation creating a layer of protection on your commercial facility.

While Single-Ply Membrane Roofing is one of the most well-known types of commercial roofing material, there are several types to fit your budget and facility needs.

There are two main types of single-ply membrane commercial roofing: Thermoplastic Polyolefin (TPO) and Ethylene Propylene Diene Terpolymer (EPDM).

They differ in their chemical makeup, how they are installed, and their energy efficiencies.

WHAT IS TPO ROOFING?

Thermoplastic Polyolefin is a single-ply roofing membrane that is one of the fastest-growing commercial roofing systems on the market. TPO roofing systems are made up of a single layer of synthetics and reinforcing scrim that can be used to cover flat roofs.

TPO membranes are manufactured in sheets that are 10, 12, or 20 feet wide. These sheets are then rolled up and taken to the commercial facility.

TPO has gained industry acceptance with the natural reflective surface to reflect UV rays. As reported by the National Roofing Contractors Association (NRCA) TPO takes up about 40% of the commercial roofing market share.

TPO ROOFING INSTALLATION

After the existing substrate is prepared, either by cleaning or removing the existing roof, the insulation is installed. There are a few types of insulation options the facility manager/owner can choose from:

- Polyisocyanurate (Polyiso) – The most used insulation type for roofing applications, Polyiso is more expensive but pays off with a higher R-value rating.

- Expanded Polystyrene (EPS) – With the highest R-value per dollar, EPS is used for roof, wall and floor insulation. EPS can be used for ground contact and does not retain water over time.

- Extruded Polystyrene (XPS) – Usually defined by the blue, green or pink color, XPS falls in-between Polyiso and EPS in the range of price and performance. XPS is semipermeable with a perm rating of 1.

The TPO membrane can be attached to the cover board with a bonding adhesive or mechanically fastened. When the membrane is rolled out, the contractor then returns and uses a hot-air gun to hot air weld the seams together.

Here's a video of the West Roofing Systems team installing a TPO Single-Ply Membrane Roofing System:

TPO ROOFING COSTS

For an average 20,000 sq. foot commercial roof, it will usually cost between $3.50 and $7.50 per square foot in materials and labor to install a typical single-ply membrane commercial roofing system.

West Roofing Systems Installs Single Ply Membrane Roof

West Roofing Systems Installs Single Ply Membrane RoofTo get the best rubber roofing prices, you will need to consider these key factors:

- The size of your roof

- The condition of the existing roof

- Access to roof

- Insulation choice

- Membrane choice

- Installation choice

- Roof penetrations

- Type of warranty

ADVANTAGES OF TPO ROOFING

If properly installed and maintained, a commercial single-ply membrane roof can last 30 years. There are quite a few other benefits of single-ply membrane roofing systems:

West Roofing Systems Installs Single Ply Membrane Roof

West Roofing Systems Installs Single Ply Membrane Roof- Customer Choice of Insulation – Since single-ply membrane roofing does not include the insulation factor, as a customer you have more options to choose from to insulate your facility's roof.

- Class A Fire-Rated – TPO membranes and EPDM can achieve Underwriters Laboratories (UL) Class A fire resistance listings by adding fire retardant chemicals during the manufacturing process.

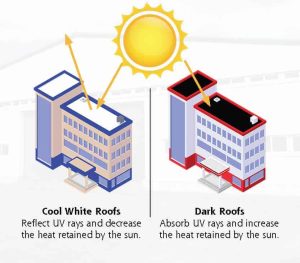

- Reflective or Retentive – TPO is generally white and highly reflective. On the other side of the spectrum, EPDM is often described as "Black Roofs," due to the natural dark color of the membrane.

How TPO Roofing Saves Money

The most common TPO material is bright white with highly reflective properties. This bright white roof installation can reflect UV rays and heat from the building, saving money during the summer months from decreased energy usage to cool the building interior.

How is a TPO roof repaired?

A TPO will last approximately 15-20 years. During this time, seams can rip apart, flashings can fail, the membrane can become punctured, etc. which will cause a roof leak.

The first sign of a TPO roof needing repair is when water has begun to enter the building. This usually happens because the seams have been ripped open, allowing water to enter the roofing insulation.

Once the insulation accrues so much water, it enters your roofing deck and eventually starts leaking on the inside of your building.

At this stage, it's time to call a commercial roofing contractor to perform a roofing inspection.

During the inspection, a roofing contractor will be able to tell:

- Where water is entering your insulation

- How old the TPO roof is

- How many layers the roof has

- What condition the seams are in

What comes out of this conversation is what repair options the building owner has. Say the roof is 12 years old and the seams are slightly uplifted, like this:

On this roof, the seams are getting close to the point of failure. If something isn't done now (or very soon), with every wind gust, the seams are separating further, which is allowing more water to enter the insulation.

A roofing contractor will perform an infrared inspection to check the amount of saturation that's in the insulation.

They will come out to your roof about 30 minutes after the sun goes down. At this time, the surface of the roof will be cooler than the water that's saturated in your insulation.

The infrared camera will detect the heat difference and the contractor will mark those areas with spray paint.

Repair options if your TPO roof has less than 25% saturation

After the infrared survey is complete, it's determined that the roof doesn't have much saturation. If your roof is under 25% saturated, then what can be performed is a silicone restoration membrane system.

What will happen during a silicone restoration membrane installation is:

- The saturated areas will be removed and replaced with similar material

- The entire field of the roof will be power washed and cleaned

- The seams of the TPO roof will be strengthened and reinforced

- Then silicone coating will be applied to the entire field of the roof

- Then a new 10-20-year warranty will be granted

Here's a video showing a silicone restoration membrane installation from start to finish:

Another scenario that happens is that although there's less than 25% saturation, the seams are in too bad of condition to restore with a silicone restoration system.

In this case, if there's only one roofing system in place, is to install a cover board over the TPO roof, cut the flashings off, and then install a spray foam roofing system. This will save you money from completely tearing off the existing roof and installing a new TPO system.

If you already have two roofing layers and the seams are in too bad of a condition to restore, you'll need to remove all the TPO and install new TPO, or a new roofing system.

Repair options if your TPO roof has more than 25% saturation

After the infrared inspection is complete, it's determined that the roof has excessive saturation. In this situation, a silicone restoration membrane system isn't beneficial. The roof is in too bad of shape to restore.

The only choice you unfortunately have is to remove all the TPO and insulation, revealing the roofing deck.

Now you can install a new TPO system. But after what happened last time, it might be cost-effective to try a different roofing system.

One that's recommended is a spray foam roofing system.

Why?

- Spray foam has the greatest r-value per square inch of thickness of any roofing system

- Spray foam is a renewable roofing system. After 10-20 years, you can recoat the roof and keep the warranty going

- Spray foam is a seamless system, eliminating a common area where leaks occur

There are more advantages of a spray foam roofing system, including how easy it can be installed.

On a TPO roof that needed to be torn off, a spray foam roofing contractor would install a cover board and simply spray foam over that.

Here's a video of a spray foam roofing installation from start to finish:

If there's anything you can take away from this section, it's that the level of saturation determines which repair options you can take.

If more than 25% of your roof is saturated, you'll need to do a complete tear-off and get all that wet insulation off your roof. If you're less than 25% saturated, you have more options.

It's very cost-effective to catch repairs early before they cause too much damage.

Next Steps? Learn more about single-ply roofing!

In our free guide, you'll learn common questions about single-ply roofing, such as:

- How much does a single-ply roof cost?

- How does a single-ply roof compare vs metal and built-up roofs?

- What are common problems single-ply roofs have?

No comments:

Post a Comment